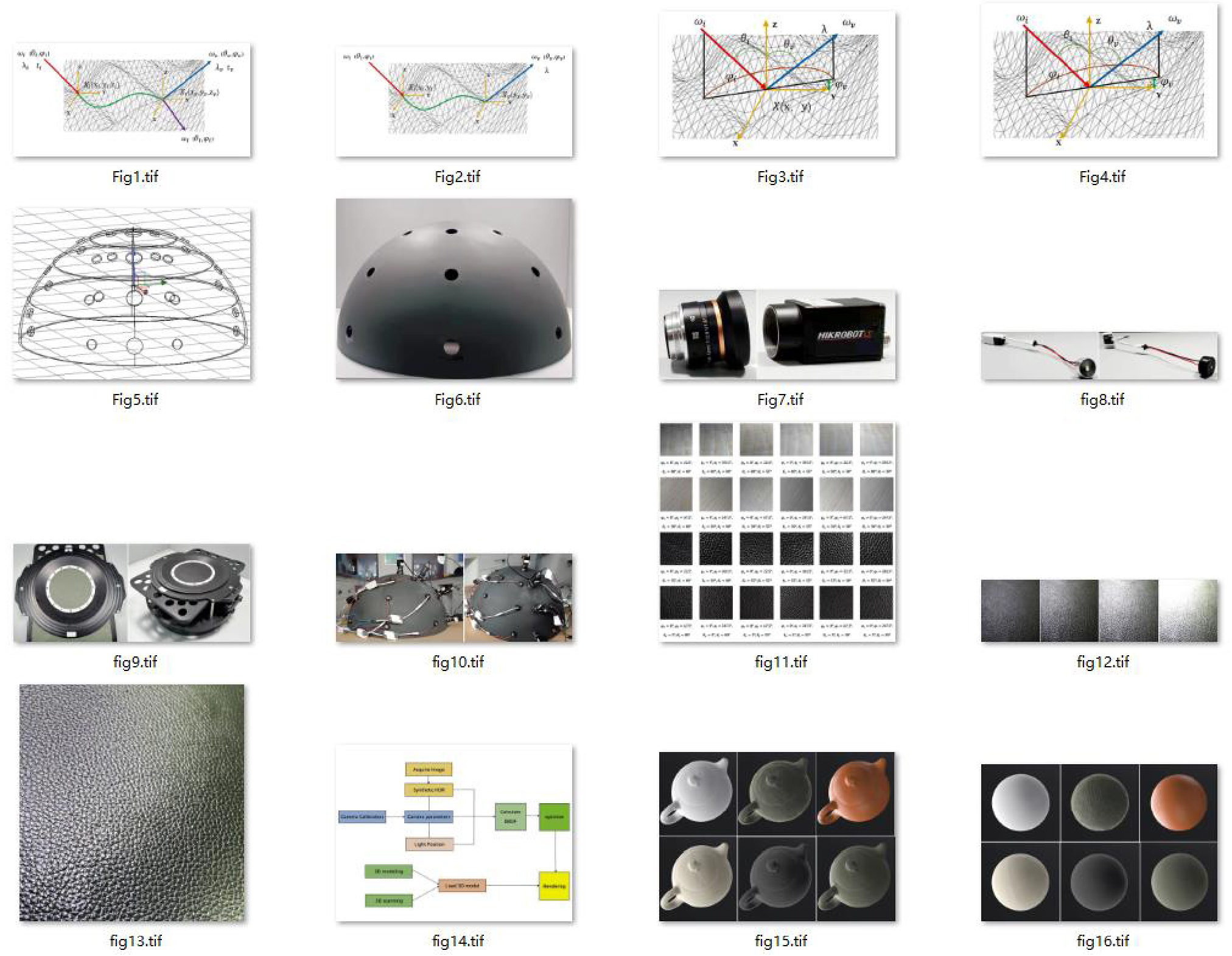

With the escalating demands for rendering technology, exclusive reliance on rendering programs is no longer sufficient. The collection of surface information pertaining to real-world materials has become a crucial aspect of computer graphics. The acquisition of material surface information is pivotal in the fields of digital reconstruction and virtual reality. In this article, we introduce a material acquisition device that employs multiple cameras and lights. This device utilizes a combination of multiple cameras and lights to capture objects from various angles and lighting conditions, resulting in more comprehensive and realistic material surface information. Specifically, the device features multiple cameras and strategically placed lighting. Four cameras are positioned at 10∘, 35∘, 60∘, and 85∘ to capture various aspects of the surface of the object while 24 point lights are placed in three layers of the hemisphere at 10∘, 35∘, and 60∘ with eight lights per layer spaced 45∘ apart. This approach facilitates the acquisition of rich and diverse material surface information by integrating multiple perspectives and lighting conditions.

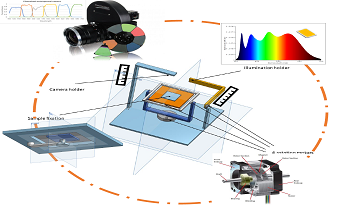

This paper introduces a novel system for measuring the appearance of materials by capturing their reflectance represented by Spatially Varying Bidirectional Reflectance Distribution Function (SVBRDF) and Bidirectional Texture Function (BTF). Inspired by goniospectrophotometers, our system uses a fully-aligned and motorized turntable that rotates the sample around three axes to scan the entire hemispherical range of incident-reflection directions. The camera remains fixed while the light source can be rotated around one axis providing the fourth degree of freedom. To ensure high precision color measurement and spectral reproduction for reliable relighting purposes, we use a high-resolution multispectral camera and a broadband LED light source. We provide an overview of our instrument in this paper, and discuss its limitations to be addressed in the future works.

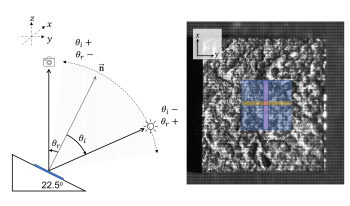

In this study, we introduced a measurement method for gloss unevenness as a function of reflectance angles. Gloss is one of the most important qualities of materials, and it is evaluated subjectively by the intensity of reflected light and gloss unevenness. People can estimate the texture of a material using gloss unevenness, which is found in the small peripheral part of the gloss area and can easily be recognized by observing the reflected light while moving the object or eyes. However, it is not easy to photograph and quantify gloss unevenness. One reason is the area where gloss unevenness is observed is a small area near specular reflection. Second, the appearance of gloss unevenness changes depending on the reflection angle. We developed a measurement apparatus to measure gonio-photometric gloss unevenness. We introduced two solutions: a wide-area gloss unevenness measurement technology using telecentric imaging and a rotating mirror optical system that defects reflected light at an angular resolution of 0.02°. We analyzed three materials—mirror, plastic, and paper—and proposed three indicators as a quantitative evaluation method for gloss: intensity of reflected light at the specular angle, full width at half maximum (FWHM) of Bidirectional Reflectance Distribution Function (BRDF), and gloss unevenness image at the FWHM.

Materials with special appearance properties such as goniochromatic materials require complex bidirectional measurements to properly characterise their colour and gloss. Normally, these measurements are performed by goniospectrophotometers which are expensive and not commonly available. In this paper a flexible imaging system composed of a snapshot multispectral camera and a light source attached to a robotic arm, is used to obtain HDR BRDF measurements of patinas commonly used in cultural heritage objects. The system is evaluated by comparing the results to those of a commercially available goniospectrophotometer. It is found that with a known uncertainty, the system is capable of producing accurate measurements of samples with a roughness equal or lower than 6.19 μm. For roughnesses higher that 12.48 μm, the accuracy of the system decreases. Moreover, it is found that the size and orientation of the region of interest plays a great influence on the precision of the imaging system.

In this study, we propose the simultaneous measurement method of the bidirectional reflection distribution function (BRDF) and the radius of curvature by using pattern illumination. For nonplanar objects, the angle of reflection light changes according to the surface normal angle of curved object. Therefore, it is necessary to consider the effects of curved surfaces when measuring the BRDF on non-planar surfaces. We suppose a convex surface that can be represented by a constant radius of curvature. The pattern of illumination was generated by placing the illumination mask with pattern apertures in the incident light path of the BRDF measurement apparatus in which the incident light is collimated light. We developed the measurement apparatus. We measured four types of sample with different BRDFs on three different radiuses of curvature. The results showed that the BRDF and the radius of curvature can be measured simultaneously by using the pattern illumination.

ICC.2:2017 is a revision to the next-generation colour management specification iccMAX that introduces new support for colour appearance processing. iccMAX includes a built-in colour appearance model IccCAM, together with a rich programming environment, and support for spectral data, material channel connections, BRDF and processing elements that make it possible to functionally encode any appearance model. ICC.2:2017 introduces many new capabilities, including the ability to provide environment variables which allow parameters such as image statistics or viewing conditions to be passed to the transform at run-time. ICC.2:2017 supports a wide range of colour appearance computations within the colour management workflow.

A system for simultaneously measuring surface normal vectors and BTF (bidirectional texture function) profiles of an object is proposed. This system consists of a correlation camera and a spherical scanning light source. The system can compress BTF measurement in one dimension of incidence direction to a single image frame, as well as measure a profile of the BTF under the scanning light source just from a single image frame. Experimental results on an implemented system demonstrate the feasibility of the proposed system.

Fourier optics system have already been recognized as an efficient solution to measure rapidly multispectral bidirectional reflectance distribution function (BRDF) of any kind of surface with very high angular resolution. This capacity is useful to study complex BRDF behaviors in particular for anisotropic surfaces. Measurement of the BRDF polarization dependence is useful to understand better the scattering processes involved in the different types of samples. In the proposed paper we show that polarimetric spectral BRDF (pBRDF) measurements are also possible using such instruments. We evaluate the accuracy of the system using black glass surface. Examples of pBRDF measurements on different types of samples (color shifting paints, car paints and gloss reference samples) are presented.

Current materials appearance is mainly tool dependent and requires time, labour and computational cost to deliver consistent visual result. Within the industry, the development of a project is often based on a virtual model, which is usually developed by means of a collaboration among several departments, which exchange data. Unfortunately, a virtual material in most cases does not appear the same as the original once imported in a different renderer due to different algorithms and settings. The aim of this research is to provide artists with a general solution, applicable regardless the file format and the software used, thus allowing them to uniform the output of the renderer they use with a reference application, arbitrarily selected within an industry, to which all the renderings obtained with other software will be made visually uniform. We propose to characterize the appearance of several classes of materials rendered using the arbitrary reference software by extracting relevant visual characteristics. By repeating the same process for any other renderer we are able to derive ad-hoc mapping functions between the two renderers. Our approach allows us to hallucinate the appearance of a scene, depicting mainly the selected classes of materials, under the reference software.

The visual impact of a product plays a key role in the consumer-perceived quality of the product. Coatings are a good solution to improve the quality of a product by either changing its appearance or add a new property, such as corrosion protection. Anodized titanium exhibits a wide range of colors, and in some cases gonioapparency, that is color changes depending on the observation and/or the illumination directions. It also offers other properties such as corrosion protection or photocatalysis. With the development of goniospectrophotometers, the colors of gonioapparent anodized titanium can be characterized but the parameters influencing the color or its gonioapparency remain unclear. The present study focuses on the influence of the roughness on the color of anodized titanium samples through measurements and optical modeling. Colors have been characterized through BRDF measurements but future comparisons between measured and perceived colors are planned. A specific device dedicated to these perception tests has been designed and is presented in the present paper.