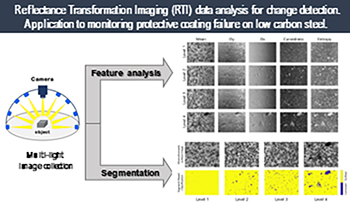

This paper examines two new methodological approaches exploring Reflectance Transformation Imaging (RTI) data processing for detecting, documenting, and tracking surface changes. The first approach is unsupervised and applies per-pixel calculations on the raw image stack to extract information related to specific surface attributes (angular reflectance, micro-geometry). The second method proposes a supervised segmentation approach that, based on machine learning algorithms, uses coefficients of a fitting model to separate the surface’s characteristics and assign them to a class. Both methodologies were applied to monitor coating failure, in the form of filiform corrosion, on low carbon steel test samples, mimicking treated historical metal objects’ surfaces. The results demonstrate the feasibility of creating accurate cartographies that depict the surface characteristics and their location. Additionally, they provide a qualitative evaluation of corrosion progression that allows tracking and monitoring changes on challenging surfaces.