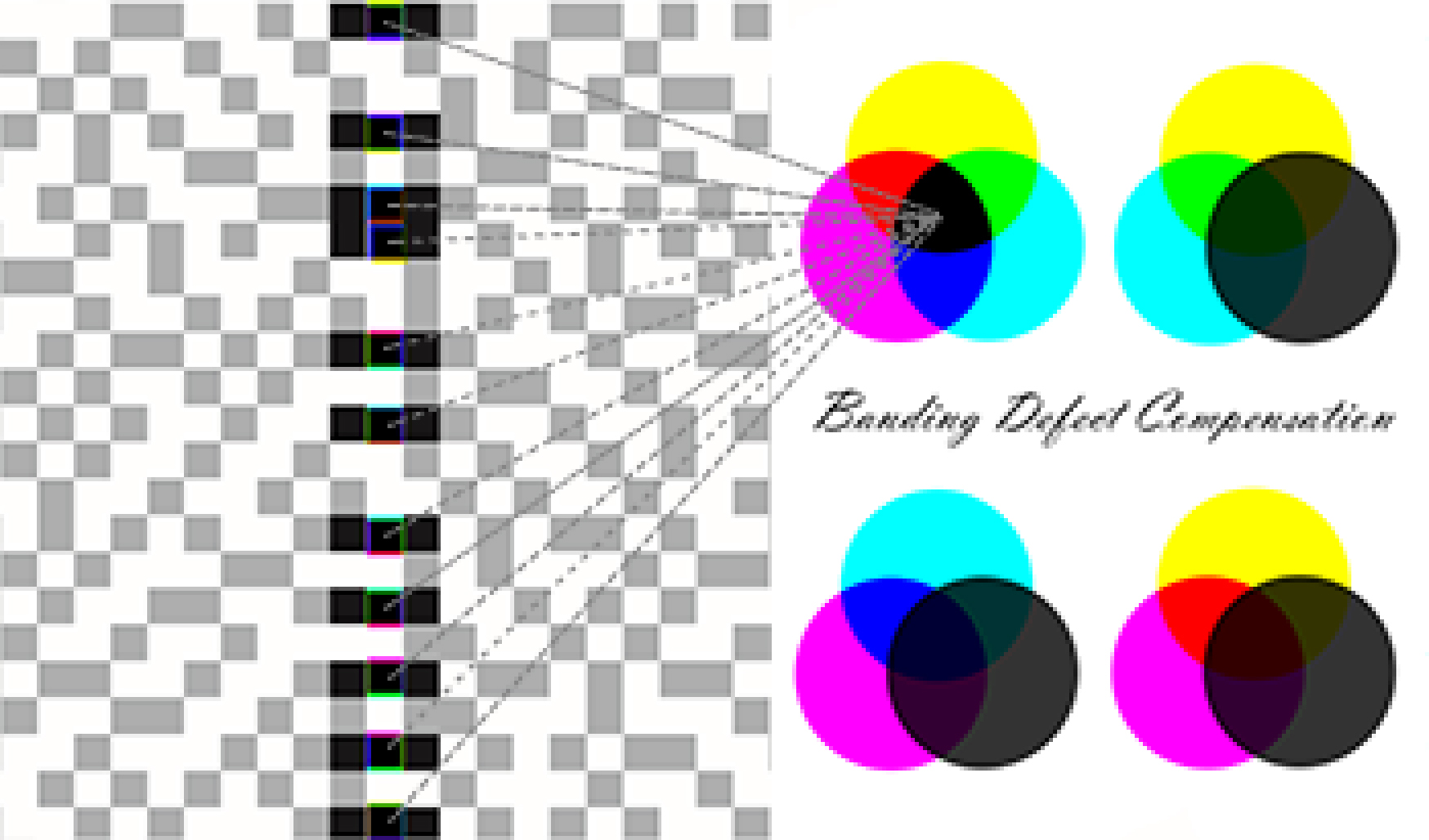

This study presents an innovative compensation technique for addressing banding defects in piezoelectric single-pass inkjet printing, a common issue stemming from nozzle malfunctions such as clogging, misfiring, and failure. The technique leverages visual perception models to dynamically optimize dot density and ink droplet size adjacent to the defective nozzle within the halftone image. It incorporates a color difference compensation algorithm based on the CIE2000 standard, ensuring uniform ink coloration across all channels and reducing density and color disparities. By meticulously adjusting the dot matrix for each printing channel at the malfunctioning nozzle, this method effectively minimizes color and density differences, making the banding defects nearly imperceptible. Experimental validation has shown a significant enhancement in the visual quality of printed outputs, applicable to both monochromatic and complex color images. Importantly, this compensation mechanism is hardware-independent, allowing for easy integration into existing digital printing workflows. This approach has the potential for broader applications beyond printing, wherever precise color and density control are critical.