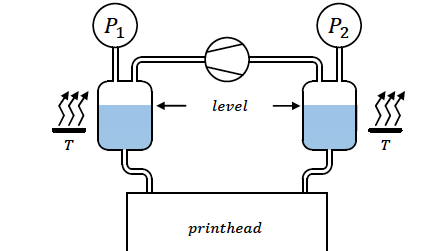

Inkjet is gaining popularity in digital production for its high flexibility, productivity and compatibility with many substrates. The core of the inkjet system is the printhead, a sophisticated device depositing ink accurately and on demand through thousands of independent nozzles. However, the complexity of the printhead presents challenges for maintenance and stable operation. Therefore, maintaining precise control over all process parameters is essential to ensure consistent quality and optimal performance. Ink rheology is an important process parameter to control. Changes in rheology caused by solvent evaporation, ink aging, sedimentation or simply a slightly different formulation of the manufacturer can lead to major quality flaws in the printing process. Commercial solutions for rheology measurements can typically only measure viscosities at frequencies of up to 10 kHz and the measurement takes place outside of the printing process. Here, a measurement system has been developed, which can monitor the rheology in the process at internal resonance frequencies of 100-200 kHz using only the printhead as the measurement device together with printing electronics which has piezo self-sensing capabilities. This system is an upgrade to a previously developed and industry tested nozzle status monitoring system that uses the piezoelectric effect to map printhead internal acoustics for nozzle failure detection.

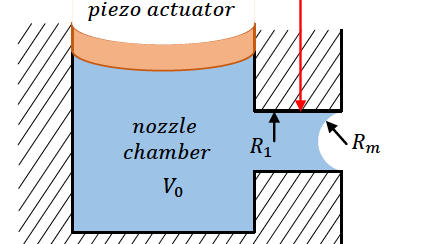

The popularity of inkjet technology is growing in the industry due to the many benefits it brings. However, the complexity of the process and hardware required to deliver a drop on demand accurately and at high speed poses a reliability challenge. With many complex parameters in the ink and printhead affecting drop quality, maintaining a stable environment is key. There has been increasing interest in sensing technologies that use the piezoelectric actuator in the nozzle to measure the acoustic response of the nozzle chamber. Several papers have been published on the use of piezo sensing to detect nozzle status. The aim of this paper is to present an innovative way of measuring the ink pressure within the nozzle chamber by sensing the piezoelectric response. Driving and measurement are performed using custom hardware to quantify the acoustic response of the system after actuation of the piezo. The variations in the dominant frequency of the response signal can then be correlated with variations in pressure. This method makes it possible to measure pressure variations along the print head, opening up a range of new possibilities for identifying events that can have a direct impact on print quality.