The Monk Skin Tone (MST) scale, comprising ten digitally defined colors, represents a diverse range of skin tones and is utilised by Google to promote social equity. The MST scale also has the potential to address health disparities in the medical field. However, these colors must be printed as physical charts for health practitioners and researchers to conduct visual comparisons. This study examines the colorimetric characteristics of the MST scale and establishes two per-patch acceptance criteria to determine the acceptability of a printed MST chart using a four-tier grading method. A software tool was developed to assist end users in printing accurate MST charts. The tool was tested with four printer/paper combinations, including inkjet, dye sublimation, and laser printers. Results show that a wide color gamut covering the brightest and darkest MST levels is crucial for producing an accurate MST chart, which can be achieved with a consumer-grade inkjet printer and glossy paper.

The Monk Skin Tone (MST) scale, comprising ten digitally defined colors, represents a diverse range of skin tones and is utilised by Google to promote social equity. The MST scale also has the potential to address health disparities in the medical field. However, these colors must be printed as physical charts for health practitioners and researchers to conduct visual comparisons. This study examines the colorimetric characteristics of the MST scale and establishes two per-patch acceptance criteria to determine the acceptability of a printed MST chart using a four-tier grading method. A software tool was developed to assist end users in printing accurate MST charts. The tool was tested with four printer/paper combinations, including inkjet, dye sublimation, and laser printers. Results show that a wide color gamut covering the brightest and darkest MST levels is crucial for producing an accurate MST chart, which can be achieved with a consumer-grade inkjet printer and glossy paper.

The surface appearance in additive manufacturing (AM) has attracted attention in recent years due to its importance in evaluating the quality of 3D printed structures. Fused Deposition Modeling (FDM), also known as Fused Filament Fabrication (FFF), holds an important share of the AM market because of its large economic potential in many industries. Nevertheless, the quality assurance procedure for FDM manufactured parts is usually complicated and expensive. The enhancement of the appearance at different illumination and viewing angles can be exploited in various applications, such as civil engineering, aeronautics, medical fields, and art. There are two steps in improving the microstructure and material appearance of printed objects, including pre-processing and post-processing. This study aims to elucidate the role of the pre-processing phase in the development of FDM parts through the assessment of color differences. For this purpose, a set of polymeric samples with different wedge (slope) angles were 3D printed using an FDM printer. The color difference between the elements is discussed and correlated with the pre-processing parameters. It is revealed that the wedge angle of the elements in the design, slicing process, and infill density could alter the color appearance of the printed parts in a predictable trend. This research suggests that low infill density and wedge angles in polylactide filaments can result in a more stable color appearance.

Inkjet printer motor control consists of moving the printhead in the scan direction and in the process direction. Both movements have different objectives. Scan direction movement needs to have constant velocity and process direction movement needs to have accurate movement. In this paper, we discuss a method for controlling the velocity of the printhead and how to tune the motor control parameters. We also design six test pages for testing accuracy of the printhead movement and cartridge properties. For each test page, we discuss expected prints, common printer control problems that could alter the print quality, and how to identify them.

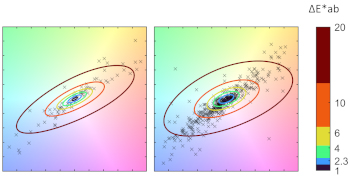

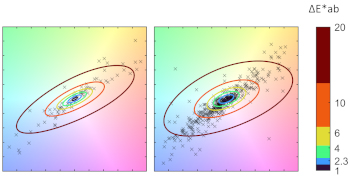

Abstract In many practical applications, printed images or text are exposed to a light source, making their lightfastness an important characteristic. Good lightfastness assures good color stability after prolonged use. In this study an accelerated aging procedure using a xenon arc lamp was applied to induce and investigate the degradation of Altona test chart color images and patches of offset and electrophotographic prints on papers made of virgin and 100% recycled fibers. In this article the authors present a new image processing method based on chrominance histogram quantification and discuss its applicability and performance with respect to the conventional spectrophotometric approach. The chrominance histogram quantification method using printed images proves to be a viable alternative to the established spectrophotometric measurements that are implemented on color patches and yield 2D color gamut information.