Professional digitization of cultural heritage items in the Polish State Archives can be divided into two major branches: digital imaging of transparencies and reflectives. While the latter has been meticulously standardized in accordance with ISO 19264 and domestic guidelines, the case is much different for the former. This paper is aimed at addressing the issue of color in mass digitization projects.

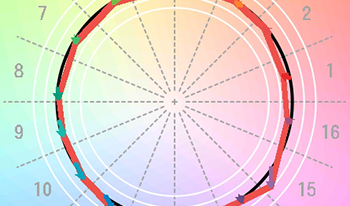

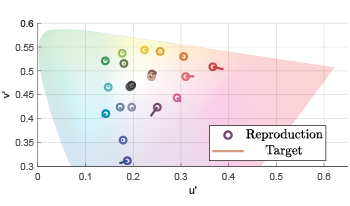

Virtual production stages with LED walls utilize illumination, display, and camera equipment which was not designed with this use case in mind. Because the spectral sensitivity of a camera is different from a human observer, a device specific calibration is required. Furthermore, the illumination spectrum emitted by the display contains large gaps in the cyan and yellow wavelength ranges and is dissimilar to the light sources for which cameras are designed. This causes object colors to be reproduced by the camera in an unnatural manner, making cinematographers hesitant to use LED walls as their primary light source. In this paper, a display calibration and camera color correction workflow for LED wall virtual production stages is proposed. A linear color correction matrix and the spectrum of a multi-channel LED fixture are jointly optimized to better reproduce object colors simultaneously illuminated by an LED display and the multi-channel fixture as they would appear under high CRI (Color Rendering Index) light sources. An alternative color correction method using root polynomials is found to further improve color reproduction. It is shown that the camera’s response to the display can be characterized by a linear 3×3 matrix and the display can be calibrated using the inverse of the color correction, allowing for a color accurate reproduction of a virtual environment.

Industrial machine vision applications frequently employ Photometric Stereo (PS) methods to detect fine surface defects on objects with challenging surface properties. To achieve highly precise results, acquisition setups with a vast amount of strobed illumination angles are required. The time-consuming nature of such an undertaking renders it inapt for most industrial applications. We overcome these limitations by carefully tailoring the required light setup to specific applications. Our novel approach facilitates the design of optimized acquisition setups for inline PS inspection systems. The optimal positions of light sources are derived from only a few representative material samples without the need for extensive amounts of training data. We formulate an energy function that constructs the illumination setup which generates the highest PS accuracy. The setup can be tailored for fast acquisition speed or cost efficiency. A thorough evaluation of the performance of our approach will be given on a public data set, evaluated by the mean angular error (MAE) for surface normals and root mean square (RMS) error for albedos. Our results show, that the obtained optimized PS setups can deliver a reconstruction performance close to the ground truth, while requiring only a few acquisitions.