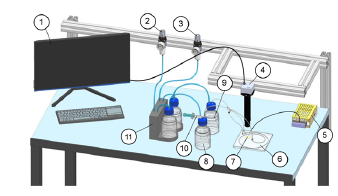

More and more functional inks are developed to enlarge the applications of inkjet printing. Yet, the stability of the inks is often challenging. For example, particles might agglomerate and clog the printhead, eventually compromising the whole printing process. Having a reliable filtering system is therefore key for complex inks. Here, we present a novel passive filtering system based on the inertial microfluidic concept that can potentially be used to filter inkjet inks in a continuous manner. The system has been first optimized thanks to numerical simulations and then characterized experimentally.

To enhance images, one often has to apply a filtering operation (denoising). However, there are several issues within the denoising. One of them is that sometimes denoising can be not efficient. Another issue regards a selection of an appropriate filter and setting of its parameters. As a particular case, we consider a 2D DCTbased filter with 8x8 pixel fully overlapping blocks where one of the parameters is a proportionality factor (PF) used in the threshold setup. We show that a performance of the considered filter in the sense of standard PSNR and visual quality metric PSNR-HVS-M can be predicted before applying image filtering procedure. This prediction is sufficiently faster than the denoising itself and accurate enough. We demonstrate that, having DCT statistics in a limited number of image blocks, such a prediction can be done for several values of PF. This allows deciding is it worth applying filtering to an image at hand. If the denoising is desired, it is also possible to select the PF optimal value for the considered image and noise intensity. Such a procedure, in some cases, can result in improvement of output PSNR or PSNR-HVS-M by up to 1 dB in comparison to the default parameters setup.