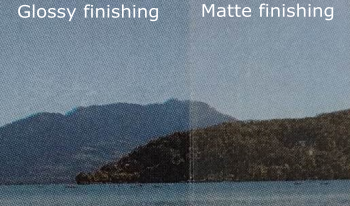

When a clear layer is coated on a diffusing background, light is reflected multiple times within the transparent layer between the background and the air-layer interface. If the background is lit in one point, the angular distribution of the scattered light and Fresnel’s angular reflectance of the interface induce a specific irradiance pattern on the diffuser: a ring-like halo. In the case where the background is not homogenously colored, e.g. a half-tone print, the multiple reflection process induces multiple con-volutions between the ring-like halo and the halftone pattern, which increases the probability for light to meet differently col-ored areas of the background and thus induces a color change of the print. This phenomenon, recently studied in the case of a smooth layer surface (glossy finishing) is extended here to rough surface layer (matte finishing) in order to see the impact of the surface roughness on the ring-like halo, and thereby on the print color change. A microfacet-based bi-directional reflectance dis-tribution function (BRDF) model is used to predict the irradi-ance pattern on the background, and physical experiments have been carried out for verification. They show that the irradiance pattern in the case of a rough surface is still a ring-like halo, and that the print color change is similar to the one observed with a smooth interface, by discarding the in-surface reflections which can induce additional color change.

Coating a printed surface with a smooth transparent layer can modify its color. This is due to light interreflections within the coating layer which produce a halo-shaped point spread function. The change of color is related to the coating thickness and the halftone screening used for printing. Thanks to an optical model able to predict the spectral reflectance of the coated print from the one of the non-coated print, we propose to study the impact of the halftone pattern (shape and profile) on the color change caused by the coating layer. It was found that line halftone patterns with a crenel profile induces the strongest changes of color. This is therefore the pattern that we use for an innovative application of this phenomenon: revealing a binary image by adding or removing a coating layer on the print that is originally uniform.