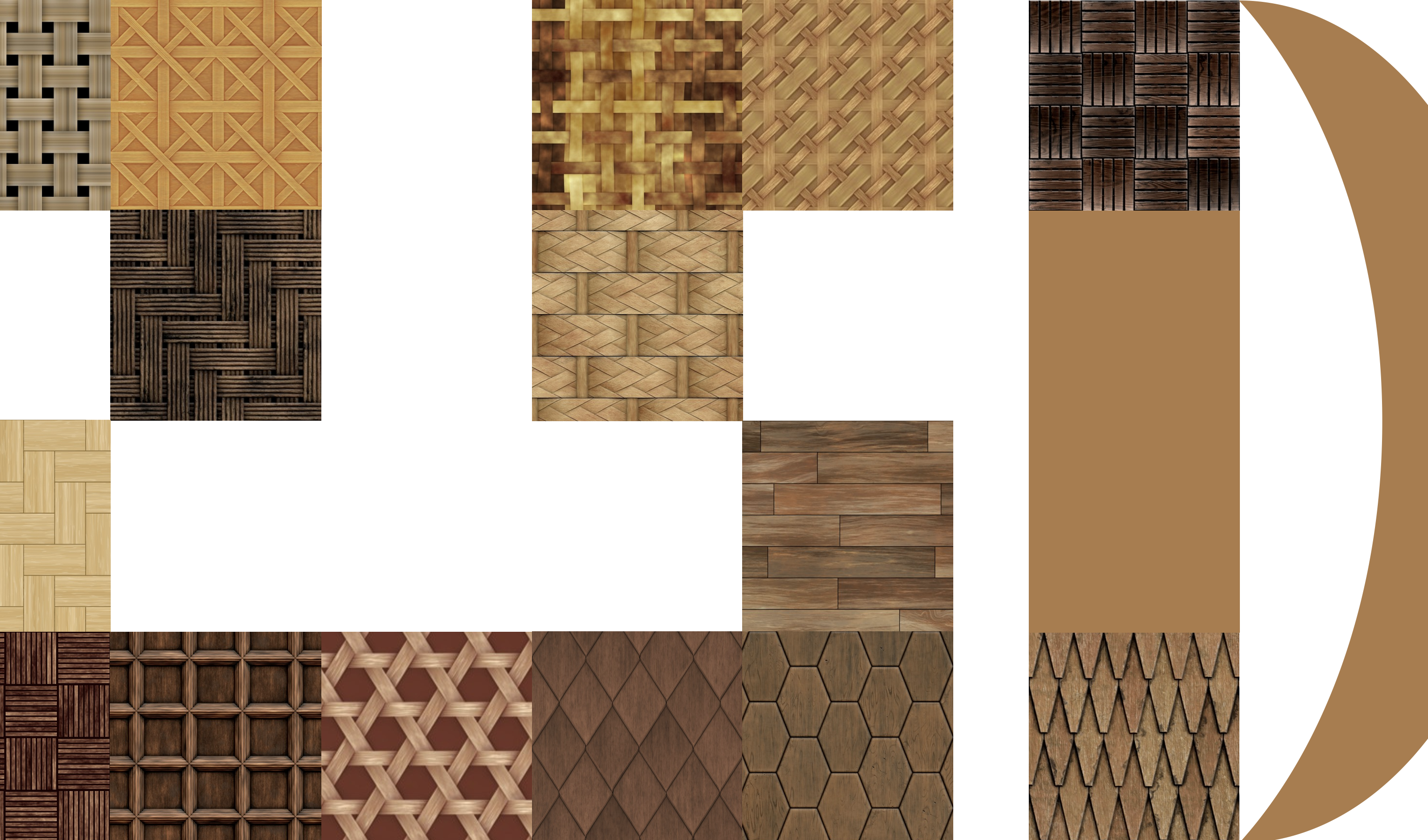

Naturalness is a complex concept and a number of parameters might impact naturalness perception. In this work, we addressed how the combination of different elevation levels and size of prints impacts naturalness perception of 2.5D prints. The results of a subjective ranking experiment showed that observers perceived 2.5D prints as more natural at higher elevation with larger size of print. Moreover, we observed that elevation seems to be a more dominant parameter than size of the print for observers when evaluating naturalness.

Perlin noise, a type of procedural noise, was used for the design of elevation files for 2.5D printing. This printing method uses elevation data from a height map to create physical relief by superimposing layers of ink. In this experiment, the grayscale values of noise functions were used as elevation values to build different surface structures in UV curable ink by 2.5D printing. Printed samples with varying levels of Perlin noise were created and their reflectance properties were studied by measuring the values of specular gloss. The roughness and specular gloss of the printed surfaces were effectively influenced when varying the persistence and octaves of the noise functions. The aim of implementing the procedural approach to a high-resolution printing method has been to explore the reflectance properties of custom noise functions when transferred to the physical realm. This might contribute to better understand the effect of surface structure on the appearance of materials. Potentially, this approach will enable the use of relief printing to produce structures with a more natural appearance and a desired gloss value by using a low-cost computing process.

The Woodburytype process is one of the only printing processes capable of producing continuous tone. It is a 2.5D process that produces a textured relief print from a gelatin-based ink that contains no photo-active element and therefore does not degrade with time. Despite all these advantages, the process is time consuming and requires the use of precision equipment to build the printing plate. We explore the initial insights into using more common additive manufacture technologies in producing both a printing plate and in ink characterization for selective deposition of the viscous gelatin ink itself.